3D printing of an (elastic) heart must be standard in every hospital (of the future)

The development process of a 3D printed elastic heart

Publication date: 2020-12-29

In the past, an anatomical model on a stand was quite normal and it is probably still on many desks in the doctors' room, or at home in the study room. It is extremely useful that parts can be taken away in order to allow inspection of deeper structures. These antatomical models however, are general models and for that reason do not provide insight into patient-specific cases.

3D Medical Lab can print patient- specific 3D antomical models! It is the first company that is able to 3D print an aneurysm with an elastic material that can match the properties of a real aneurysm. The use of these 3D printed models opens the way to surgically treat complex and challenging aneurysms. See also our article: Surgically treat patients with an aneurysm faultless when using 3D models

We have done a lot of research into 3D printing of elastic vascular models and now we will also focus on the 3D printing of an elastic heart.

Nowadays, there are approximately one and a half million cardiovascular patients in the Netherlands and nearly 750 people with cardiovascular problems are admitted to hospital every day. 100 Dutch people die daily from this disease.

A 3D printed heart can provide the surgeon the opportunity to gain more insight into the complexity of a patient case by studying the 3D model, which can prevent failures in the operating room. In addition, 3D models can also help to train surgeons. At a time when cardiovascular disease is still a common cause of death, 3D printed innovations can save the lives of many people worldwide on the long term.

Medical specialists can practice and test surgical techniques in a laboratory on a pig's heart. With the right technique, the pig's heart can be a valuable research object, however it also has many drawbacks. Some surgeons do indicate that the pig's heart is weak, and multiple fluids are released, with the need for thorough cleaning afterwards. And surgeons have to practise in a - not optimal- laboratory setting. 3D printed patient specific models will take away these drawbacks. In current time, the use of an animal heart is no longer desirable and should have to be replaced.

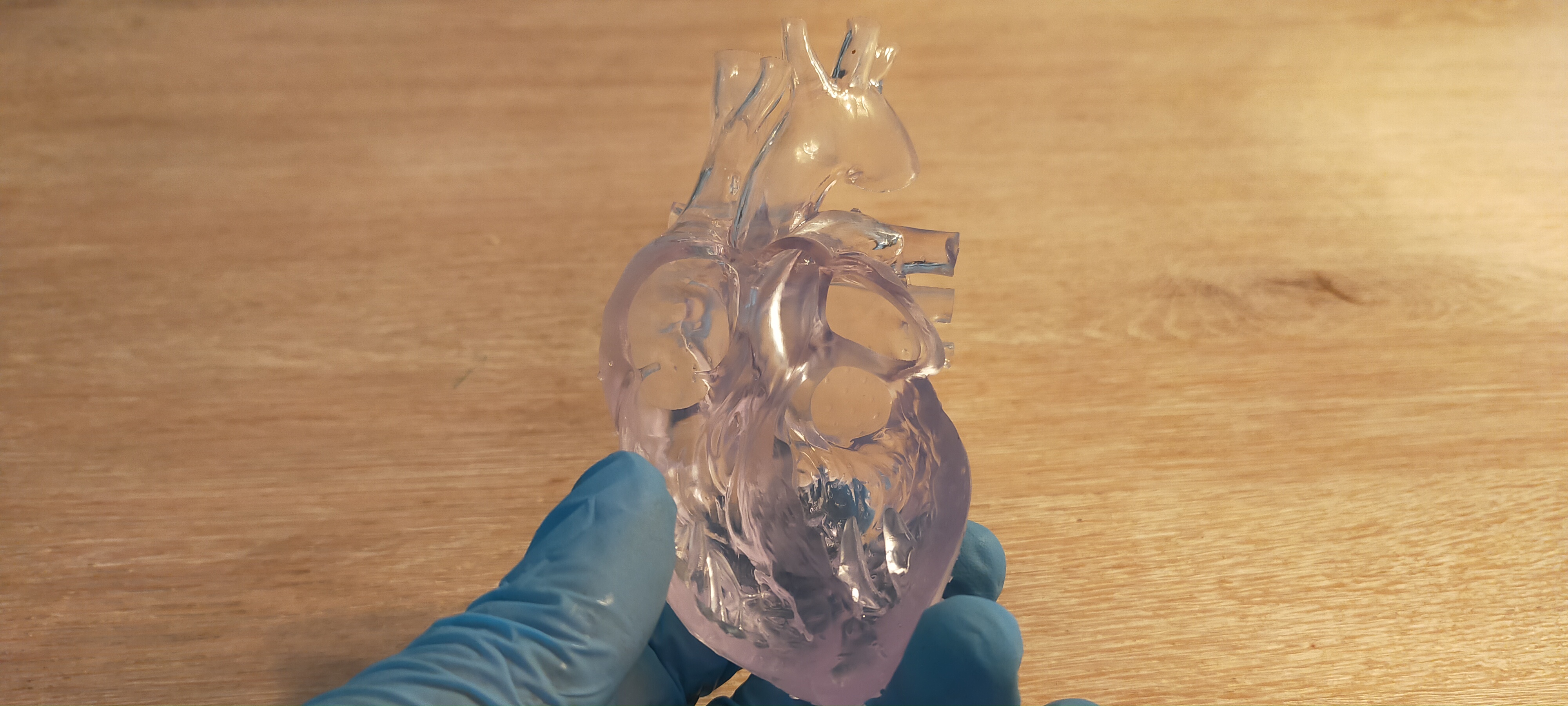

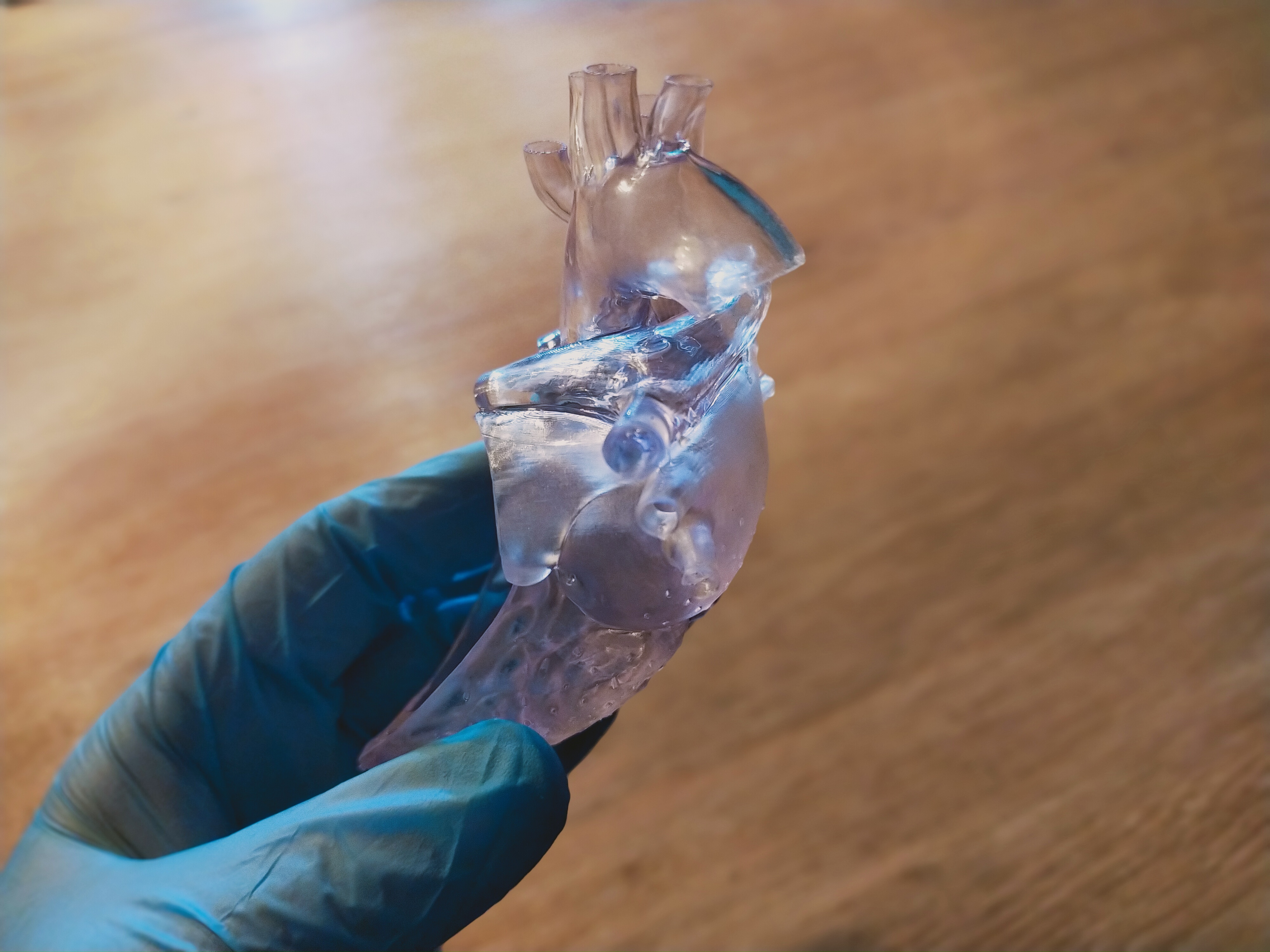

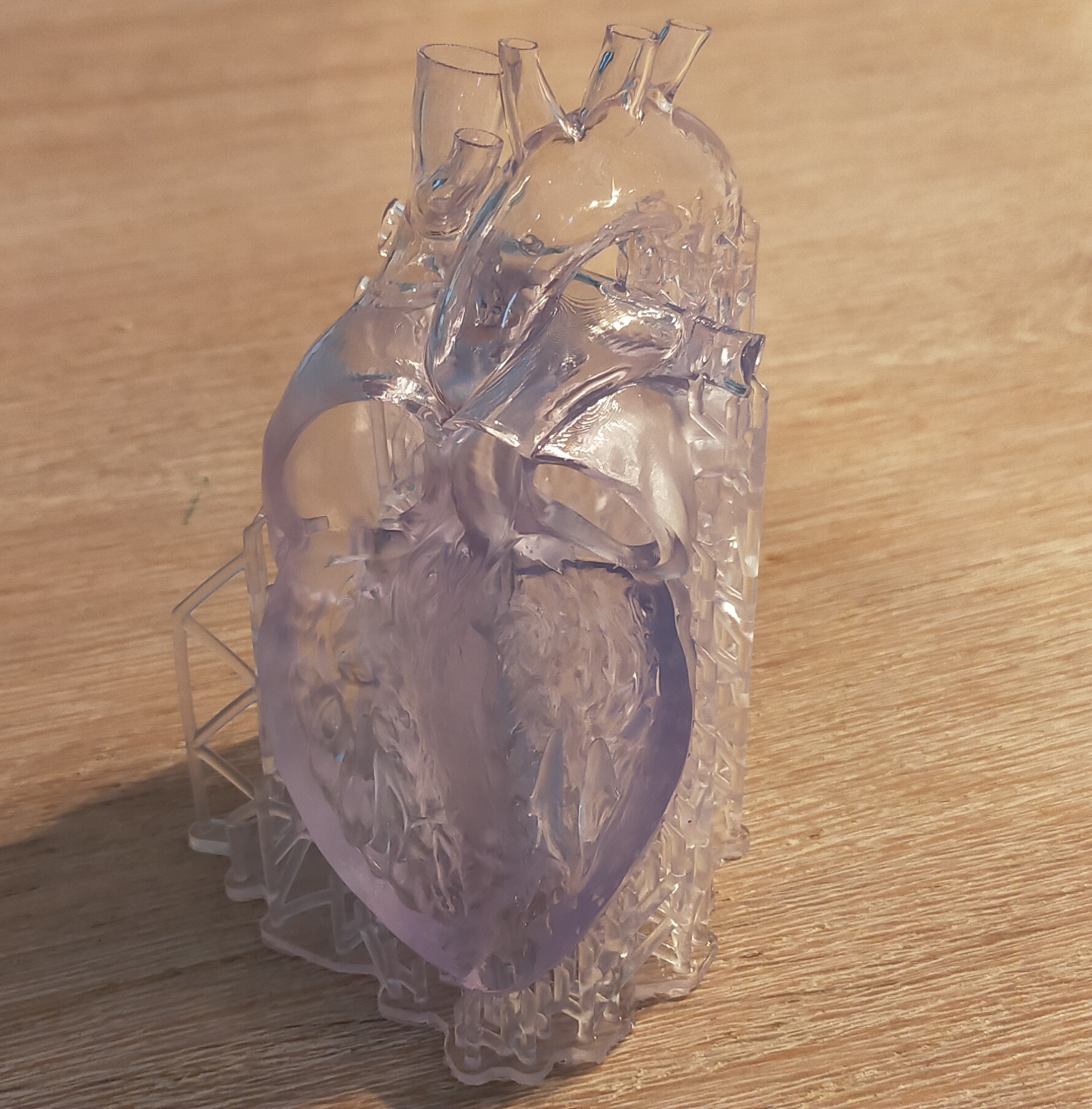

A 3D printed heart or vascular model has many more advantages. A specific complex operation can be well prepared, by specifically printing the heart of the patient. The 3D printed heart model is elastic and can therefore reasonably approximate reality. It is transparent, so that you can understand how the structures run and if you are practicing a surgical technique, you can see what you are doing. In addition, you can also run liquids through it, in order to simulate the flow pressure. In this way, you are able to investigate the pressure applied to the heart valves.

Are you curious to what our 3D printed heart will look like? Take a look below at the description

We are very curious about the impact our 3D printed cardiovascular models will have on the long term. Only time can tell us...

For more information, please contact: contact@3DMedicalLab.com

Contact Us

contact@3DMedicalLab.com

3D Medical Lab is onderdeel van :

Technical Medicine Solutions B.V.

Oudegracht 275C

3511NN Utrecht

The Netherlands

contact@3DMedicalLab.com

3D Medical Lab is onderdeel van :

Technical Medicine Solutions B.V.

Oudegracht 275C

3511NN Utrecht

The Netherlands

Follow us

©2021 KvK-nr: 73035114 BTW-nr: NL859328855B01 IBAN-bankrek.: NL24INGB0008665180